Engine Management Woes

MB27, the trials and tribulations

The history of this started on the way back from the Lancaster bomber visit in June 2018 as an intermittent fault and finally, early last year, the engine cut out and would not restart. Pete got a mobile engine tuner who diagnosed a fault with the distributor or module. A new old stock distributor was found courtesy of Mark Wilson and when fitted the car would start but still stalled at idle. Irritatingly it would stop stalling when it was warm. However, another trait was that it would not rev above 4,000rpm. After a bit of playing around the limit became 5,000rpm. Not normally driving at these revs (Oh yeah?) Pete did not know if this was new or a pre-existing condition. He borrowed a known good distributor and got the same symptoms, so back to the drawing board.

To cut a long story short, in various combinations he swapped 3 rotor arms, 3 potentiometers, 2 coils, 2 throttle pots and cold idle valves. He also replaced the air flow meter with a known good one to no effect. He also replaced the air filter, petrol filter and several sets of plugs with different gap settings and new plug leads and a distributor cap. The only change after all this was that the car would now cut out when hot as well as cold.

Admitting defeat, Pete sent the car to a Scimitar specialist where it resided for 3 and a half months. They repeated much of what Pete had tried but in different combinations, plus 2 coolant sensors and two ECUs. The car was tried without the exhausts on and with the engine earthed to the battery. There was a suggestion that the camshaft might be worn leading to the high rev issue. So, out with the engine and in with a replacement sourced from a TVR S2. This engine, having only covered 60,000 miles, came with all the ancillaries. The only change was that the cold start was even worse.

The compression was checked, fine. The fuel pressure was checked, fine. Then an auto electrician was brought in to check the loom and repaired several "dodgy" connections. No improvement. The car was run with the fuel cap open, fuel pump relays changed and two tanks of different petrol. It was getting desperate now and straws were being clutched big time so he toured the NEC in November 2019 for Ford specialists who might be able to help.

After the NEC he had two 3 hour round trips to a specialist in Swindon. The initial visit identified the issue with the cold start but the ECU could not be put into service mode until that was fixed, hence the second visit. By this time it had started surging and would still not rev properly. It had also started cutting out when hot or cold at low revs and was juddering at low revs that coincided with the volt meter dropping from 13.5v down to 12v and then bouncing straight back up again.

Pete says that this problem with the voltmeter had appeared on and off for the past 12 years. A long time ago it was found that water had dripped through the driver's side wiper gear box and into a multi plug for the main ignition circuit. This occasionally arced and stalled the engine. So, to eliminate this out came the speedo and all the wiring was renewed. Well, it still juddered occasionally.

As regards the surging - yet another new potentiometer fitted and this improved things slightly but he was sure he could hear air being sucked in so also did the inlet manifold and plenum gaskets. He found 3 bolts finger tight that were holding the fuel rail in, hooray! Surging fixed.

Then he went into earthing mode in the engine bay: coil, alternator distributor and extra straps to the battery and both sides of the engine. By accident he found, once the car was warmed up, that if he unplugged both the potentiometer and the idle valve connectors, the car drove very well with no stalling issues or juddering.

So, into earthing mode on the ECU, six found in total, did all them. No good. Stripped back what he could of the wiring loom to look for damage. None found.

So that's when straws stopped being clutched and the white flag was hoisted. Pete delivered the car to another specialist who suggested a complete new ECU and control system including:

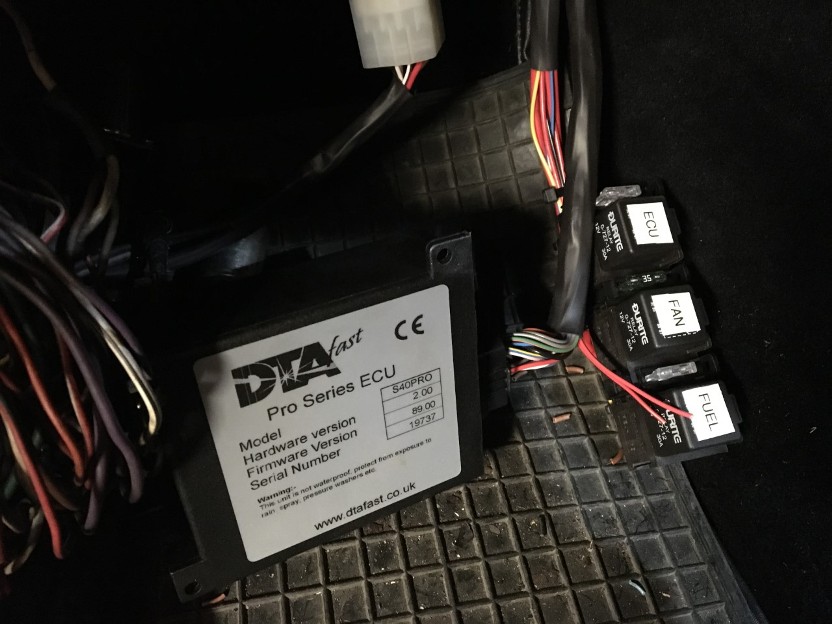

1. Installation of a DTA ECU to take full control of the engines fuel and ignition system with data sensor feeds from the throttle position sensor, water temp. sensor and air temp. sensor.

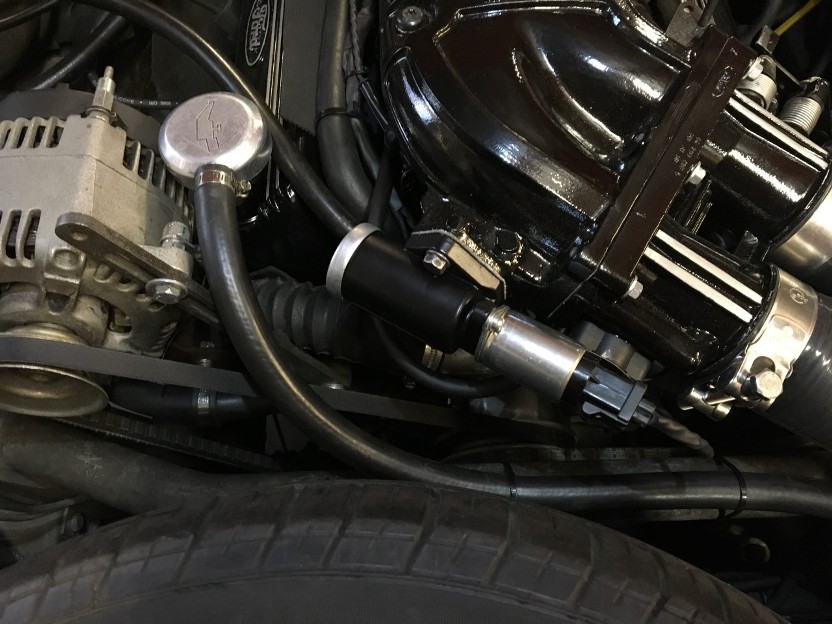

2. Installation of a crank trigger wheel on the front pulley for a crank position sensor.

3. A new wiring loom to all sensors and auxiliaries in the car

4. The ECU set up to control pumps, fans etc.

Finally, the car would be mapped on a rolling road to gain the best performance from the engine.

The photos show what came out, including the control unit for the Kenlowe fan, followed by a picture of the engine bay. Next picture the pulley sensor. Laser cut with a bespoke mounting bracket. The wiring for that sensor is special, coming in at £38 a metre, then the ECU and associated relays.

It is not a wasted spark system. The specialist had a rethink and decided to keep it as original looking as possible. At first glance you would not know it has been modified. It now has a bespoke wiring loom with all new plugs and connectors, even for the injectors. The company had to source bits in from all over the place, including a different temperature sensor in the cylinder head for the fan as they reckoned this is a better place to take the reading from in case the thermostat ever packs up.

They checked with the manufacturer of the ECU and this is the first time it has been fitted like this to a V6. They spent 6 hours mapping it on the rolling road and confirmed it is producing 162 BHP at the flywheel. It has been electronically limited to 6,000 revs and the ECU can be bluetoothed to a mobile phone to show real time data if you so wish. A laptop can be plugged into it and the company can remotely access it from anywhere in the world. On the initial test drive they checked and Pete had hit 5,248 revs. (Never normally drives at >5,000 revs huh?)

So, after all this what did it drive like? Pete says like a gas turbine. The engine that came out was 3.1 with stage two heads and a rally cam shaft that originally produced 210 BHP. This TVR engine, although way down on BHP, felt just as fast; turning right at a junction on a wet road and the wheels spin, loose gravel when pulling onto a roundabout and the wheels spin, just like the old engine used to. It's best described as fifth gear being more like fourth gear.

There was an issue with hot starting and stalling at low speed pull off. Two more hours on the rolling road cured these issues. It is now mapped it to pull away at 800 revs without stalling!

So the car has retained its original look and with the spare wheel in situ you will struggle to see the crank sensor. It has retained and uses the distributor and coil but has done away with the air flow meters and the idle control valve. If you look closely at that you will see a dummy wire cable tied to it and Pete intends to put the old plug on it to make it look original. It absolutely flies.

We will leave the cost element out of this but the final bill for the rewire and ECU was about 30% of the cost of all the work prior to that. All I can say is that Pete must really love the car because at various points during this saga when he was contacting some of the owners for help and support at least two of the suggestions (one of which might have been mine!) involved the Samaritans and/or a box of matches. It's nice when your fellow owners are so understanding!

(All photos aand data courtesy of Peter Humphries) MB 27